Guidelines like CFR Title 21 established forth the necessities for your manufacturing, processing, packaging & storage of pharmaceutical goods to ensure they meet security & quality specifications.

Grouping of items created in identical devices chains from which the worst-case product or service are going to be selected according to batch measurement, solubility, each day doses, and therapeutic dose.

The product or service obtaining the worst solubility profile of their cleaning solvent/media shall be selected given that the worst situation merchandise within the criterion.

Checking supplies worthwhile details about the general performance of cleaning techniques and helps discover any deviations or failures that need to be dealt with.

Validation Master System: Creating a validation learn plan that outlines the overall validation approach, like cleaning validation, is very important for retaining consistency and compliance.

I'm able to revoke my consent at any time with effect for the future by sending an e-mail to unsubscribe@sartorius.com or by clicking around the "unsubscribe" hyperlink in e-mails I have gained.

Obtain the swab/rinse sample of every bit of kit associated for manufacturing soon after remaining cleaning According to the authorised sampling strategy.

Efficient Education and Documentation: Proper instruction of staff linked to cleaning validation is crucial to be sure steady execution of cleaning procedures. Coaching need to deal with the importance of cleaning validation, right cleaning methods, and click here the usage of correct cleaning brokers.

For most scenarios, the selection check here in the Restrict relies on affected individual security; even so, you can find other factors that may effects the choice, demanding more evaluation. The complex and excellent persons are responsible for the ultimate conclusion with proper justification.

A cleaning validation for a family members of compounds using swab sampling and rinse Alternative techniques, and significant overall performance liquid chromatography for separation and detection in the analytes was done.Helpful parameters on recovery including sampling method, swab traits, solvent, swabbing approach, and materials compound of item Call surfaces throughout the manufacturing tools for swab and rinse sampling method, quantitative cleaning verification method, and Energetic pharmaceutical component (API) amount and mother nature have been examined.The Restrict of detection plus the limit of quantitation for the HPLC method were being established to generally be 0.0198 µg/mL, and 0.0495 µg/mL on the analyte, respectively.

Aside from our Extractables Evaluation, we also present Extractables Studies to recognize and stay away from probable leachables towards your final drug solution. Extractables Experiments are just what you will need during the selection of acceptable packaging components or processing tools, e.

This strategy makes sure that cleaning attempts are targeted the place they are most necessary, reducing the chance of contamination.

The repeat of Preliminary validation both following alterations/introduction to devices, new solution or periodically to deliver assurance the alterations are completed, will not have an impact on the cleaning usefulness.

Guide cleaning: Manual cleaning involves cleaning gear & surfaces by & with cloths, brushes & cautiously picked cleaning agents.

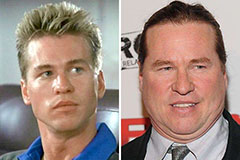

Val Kilmer Then & Now!

Val Kilmer Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!